Fast-forwarding the Forces of Nature: Proving and Improving Epoxy Strength

4 September 2025

At Megapoxy, our promise isn’t just strength at application: it’s strength that endures. Australia’s intense UV, sudden storms and humid nights demand solutions that don’t simply hold, but last. That’s where our UV Weathering Testing Chamber comes in.

Why we test

The chamber lets us replicate years of climatic exposure in days: like temperature shifts, condensation and moisture.

It helps identify early signs of ageing like:

- browning, fading and discolouration

- loss of gloss or brightness

- chalking, blistering and cracking

- brittleness and surface breakdown

- oxidation and surface degradation.

These insights give our Quality and R&D teams the data to improve formulations, validate performance and deliver solutions that are proven to last.

How It works

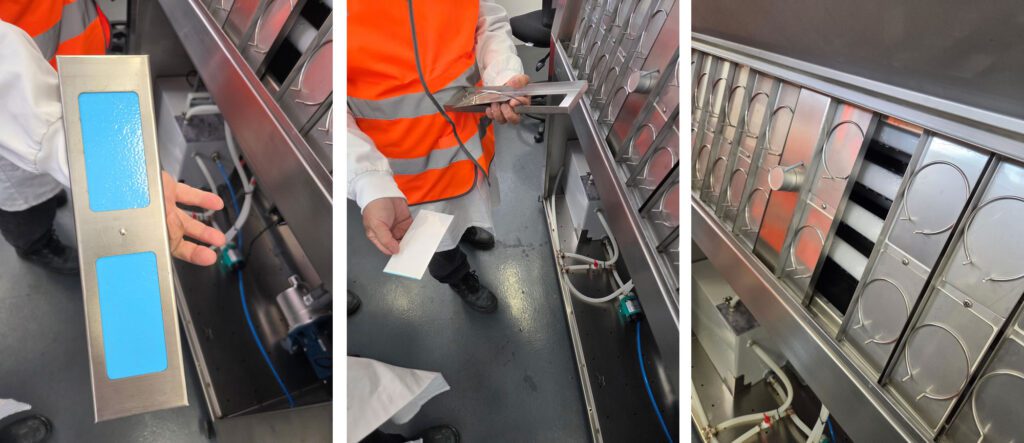

UV weathering test equipment simulates the destructive impact of sunlight, dew and rain. Our chamber uses fluorescent UV lamps to mimic the short-wave UV portion of sunlight – responsible for most photochemical damage – while cycles of condensation or spray simulate moisture exposure.

Inside the chamber, coated panels are exposed to cycles of UV light, heat and moisture – created using steaming and condensing technology – until the first signs of ageing appear. A few days or weeks in the chamber can reproduce months or years in the great outdoors – exposing damage pathways long before they would appear in the field. Because humidity cycles in nature often last up to 12 hours, the chamber alternates UV and condensation cycles separately, ensuring accurate simulation of outdoor conditions.

Why it matters for coatings

For our coat, paint & protect range, clarity and durability are vital.

By weather-testing these coatings, we can:

- detect early yellowing and gloss changes

- prevent brittleness and cracking

- validate resistance to chalking under moisture cycles

- fine-tune formulations with stabilisers or additives for longer-lasting clarity and strength

Benefits across the range

While validating coatings, the chamber also supports our adhesives, structural systems and other epoxy solutions.

- Faster, lab-verified durability performance.

- Accelerated validation of new formulations.

- Greater confidence in batch-to-batch consistency.

- More sustainable product development, with fewer failures and rework.

Backed by people and science

Behind every test is our team of chemists, technicians and specialists who translate data into real-world reliability. By combining accelerated weathering with mechanical testing, we ensure that every Megapoxy solution is both functionally durable and visually resilient.

Ready to test the limits? Read more about our quality control systems and talk to us about your specific project needs.