A breakthrough in deep grouting for modern industry

10 February 2026

The innovation that cuts time, labour and complexity for deep-pour epoxy grouting.

In heavy industry, mining and infrastructure, the stability of assets is essential. The grout beneath critical equipment plays a direct role in alignment, vibration control, wear and ongoing reliability – particularly where grout sections are deep and loads are high.

Until now, deep epoxy grouting has typically required staged pours and added aggregate to manage heat build-up. This increases costs and labour, making large pours and tight installation windows even more challenging.

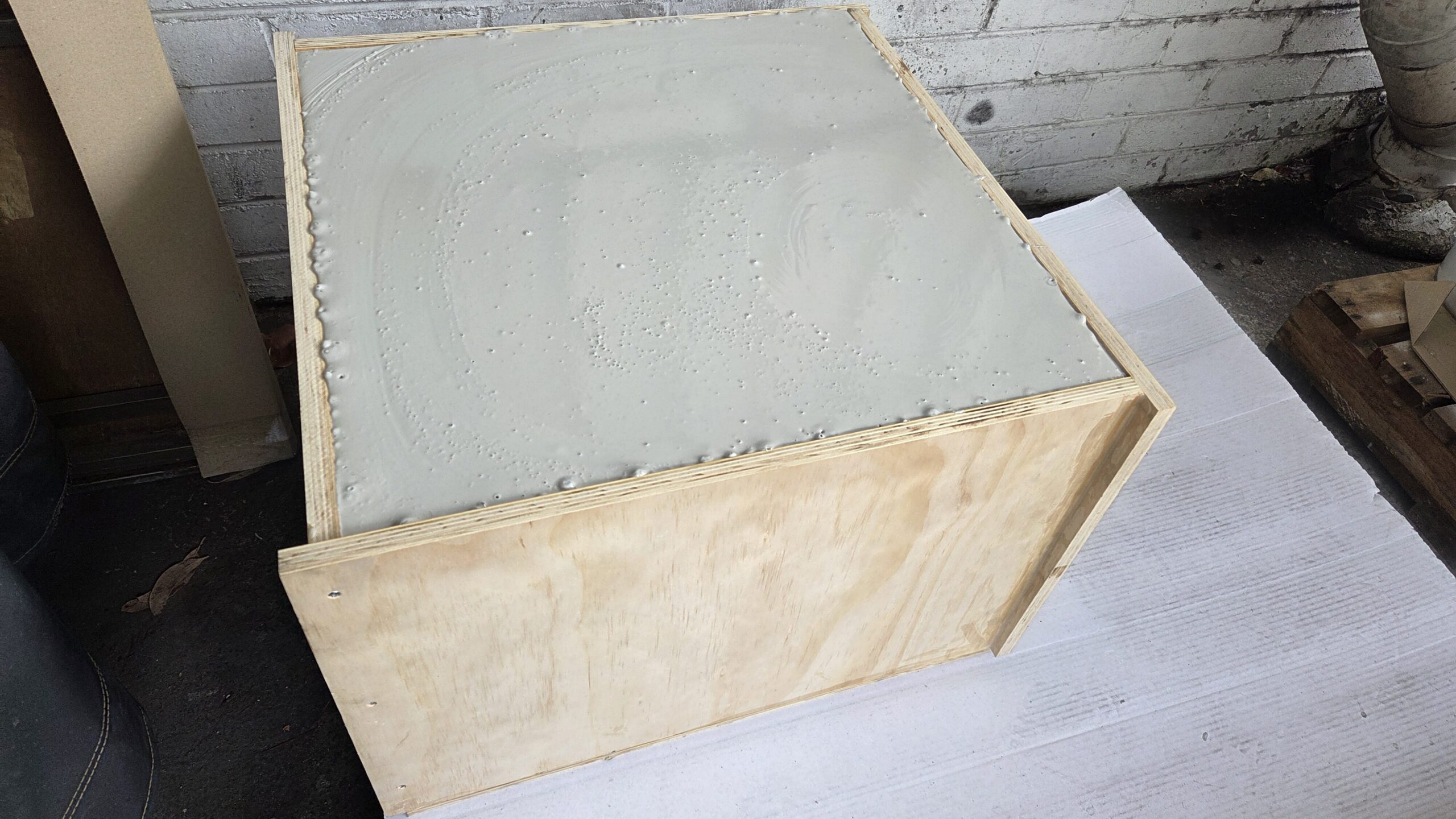

Megapoxy Deep Pour Grout represents a step change, enabling deep grout sections to be completed in a single continuous pour.

- Traditional approach: staged pours with added aggregate.

- With Megapoxy Deep Pour Grout: single continuous pour from 50–300mm, without aggregate.

By controlling heat through its chemical formulation, this new formulation removes the need for added sand or gravel. It’s a simple two-part system that reduces handling and time onsite, while delivering the strength and long-term stability that industrial and infrastructure assets depend on.

Applications for deep-pour epoxy grouting

Because it contains no added aggregate, Megapoxy Deep Pour Grout achieves higher compressive strength than many epoxy grouts on the market, while still allowing greater pour thickness in a single application.

This makes it well suited to machinery bases and skid plates for compressors, crushers, mills, pumps, generators and turbines: where high loads, precise alignment and vibration control are critical to equipment performance.

The aggregate-free formulation also eliminates dust, supporting safer working conditions and easier compliance with site and regulatory requirements, especially in enclosed or operational environments.

Megapoxy Deep Pour Grout is also used in structural grouting applications such as bridge bearing pads, rail and crane rail systems, large base plates and truncation pockets.

Across mining, heavy manufacturing, transport infrastructure and water and wastewater assets, it is particularly valuable for time-critical installations and shutdown work – including hot or demanding site conditions – where clean handling, predictable curing and consistent performance matter most.

Epoxy grout for any pour depth: the fit with 206 Ultra

Megapoxy 206 Ultra is a proven, high-strength epoxy grout for machinery and structural applications, typically used for pours up to 50mm. Megapoxy Deep Pour Grout extends this capability for deeper sections of 50mm to 300mm, with application in a single, continuous pour.

Together, they provide a straightforward way to match grout selection to specific project needs, with efficient installation across both shallow and deep applications.

- Up to 50mm: Megapoxy 206 Ultra

- 50–300mm: Megapoxy Deep Pour Grout

- Where heat control is critical: Deep Pour Grout may also be used in sections from around 20mm.

Performance beyond installation

The value of Megapoxy Deep Pour Grout continues long after placement.Stable equipment alignment and baseplate support are critical to both performance and safety, particularly for large rotating machinery and heavily loaded structural elements. Consistent grout support supports smoother operation and reduces transmitted movement and noise through surrounding structures.

By limiting uneven load transfer and movement at the foundation, Megapoxy Deep Pour Grout helps reduce wear on bearings, shafts and connected components. Over time, this can translate to fewer maintenance interventions, reduced component replacement and longer service intervals.

Looking for the right grouting solution?

From standard machinery grouting to deep, large-volume applications, Megapoxy offers epoxy grout systems designed for specific uses and supported by technical expertise. Explore our grouting solutions, download technical data sheets, or speak with our team about your next project.