No stone unturned: Smarter stone fabrication and tile epoxy solutions

4 December 2025

How epoxy adhesives support stronger stonework designs, cleaner finishes and onsite efficiencies.

Stone fabrication and tiling have never been more demanding. Architectural facades, innovative building materials, curved ‘organic’ shapes, exacting specifications and new manufacturing technology all call for next-level precision, strength and reliability.

That’s why more specifiers, installers, fabricators and builders are turning to stone and tile epoxy systems. Whether it’s creating seamless mitred corners for marble benchtops, reinforcing slabs before fabrication, or spot-fixing heavy sandstone to challenging substrates, epoxy is helping achieve the best results with simplicity and confidence.

Stone cladding: tile epoxy for marble, granite & sandstone fixing

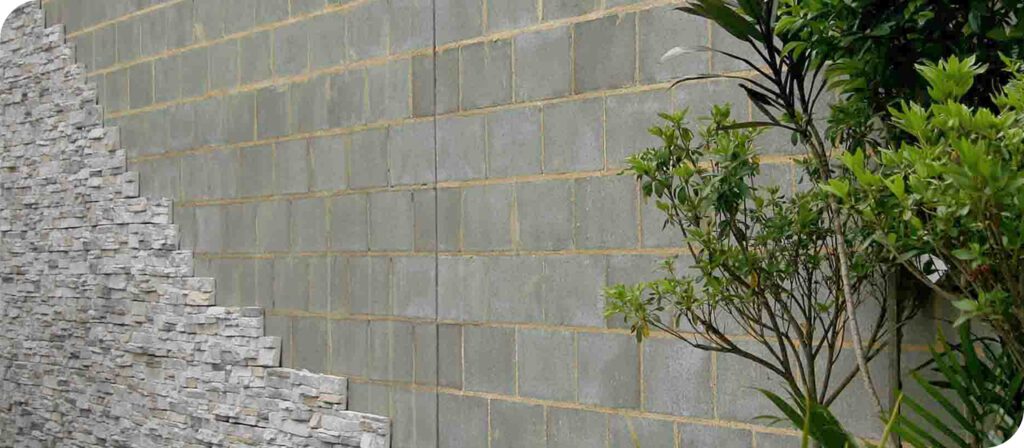

Stone cladding calls for adhesives that deliver certainty on real sites: where walls aren’t always straight, substrates vary, and stone needs to adhere and hold permanently.

Tile epoxy systems, such as Megapoxy PM and Megapoxy PF, provide exceptionally strong bonds to concrete, masonry and fibre cement. Designed to accommodate movement and temperature changes, they perform in environments exposed to heat, wind and vibration. Being non-slump, they don’t sag or run, which makes them ideal for vertical and overhead applications.

Spot fixing is one of the best methods for applying high-quality tile epoxy, where small, evenly spaced spots of adhesive are applied to the back of each panel. This method creates a ventilated cavity, improves acoustic and thermal performance, and avoids the need for rendering or plastering. Suited to uneven and out-of-plumb substrates, Megapoxy’s solutions provide a powerful hold with just 10% surface coverage, when applied correctly to each tile.

This approach was perfect for an upmarket apartment façade, requiring the installation of new stackstone over an out-of-plumb precast concrete wall. After grinding back old adhesive and preparing the surface, installers used a simple three-spot method with Megapoxy PM to achieve permanent bonds. The solution provided robust, long-term durability in a busy pedestrian area, while delivering high-end architectural style.

Epoxy systems for fabrication: stronger slabs, cleaner joins, seamless details

For stone fabrication, epoxy plays an essential role in achieving clean finishes and precise details.

Different formulations are used to fix chips and cracks, reduce porosity and water absorption, and increase structural integrity. Clear or colour-matched formulations help blend repairs into the stone, while low-viscosity resins can penetrate into fissures and flaws.

Thin, brittle or exotic marble can be strengthened and reinforced by applying fiberglass mesh to the back of the slab with epoxy resin as the bonding agent. It’s widely used in countertop fabrication, wall cladding and other applications – reducing the risk of damage during handling, transport and installation.

For detailed work, adhesive gels such as Megapoxy 63 deliver crisp mitre joins, thin glue lines and smooth finishes without shadowing or picture framing on light-coloured stone. This level of control was crucial for Gitani Stone during the manufacture of its exquisite marble benchtops. Megapoxy 63 provided the impact resistance and translucency needed, curing within 24 hours so the bench could continue through the next stage of fabrication without delay. The result? A clean, seamless finish that matched the premium quality of the material itself.

Waterproofing and bonding: a breakthrough in tile epoxy

Securely bonding natural stone to waterproofed vertical surfaces has long been a challenge. Traditionally, waterproofing membranes haven’t been guaranteed to support the weight of stone, leaving installers reliant on mechanical fixings or complex workarounds. As facades and exterior cladding become more ambitious, project teams need an approach that both seals the substrate and creates a dependable base for stone fixing.

Epoxy solutions like Megapoxy H offer a practical alternative for porous substrates such as concrete block, precast or in-situ cast concrete, and cement-based fibre board. Applied in multiple coats, Megapoxy H acts as both a primer and sealer, forming a waterproof layer that integrates into the substrate. Because it is compatible with tile epoxy adhesives such as Megapoxy PM, stone can then be fixed directly and confidently to the prepared surface.

This approach was central to a sandstone facade project on Sydney’s Northern Beaches, where the CFC sheeting needed both strengthening and waterproofing before heavy stone tiles could be applied. Using Megapoxy H with a fine aggregate created the ideal surface for reliable adhesion. With the simple spot-fixing method, flat sandstone tiles were then bonded to a curved surface using Megapoxy PM White – delivering a premium finish designed to endure for generations.

Looking for the right stonework & tile epoxy solution?

Explore our natural stone solutions, browse our resources, find a stockist or distributor near you, or ask for advice today. We’re always here to help.