Engineered for water infrastructure

Water facilities (including wastewater) demand materials that withstand moisture, corrosion, chemicals and constant operational pressure.

Our epoxy adhesives and waterproof coatings help to protect and strengthen water assets for longer service life – from dams and reservoirs to pipelines and treatment plants

Megapoxy built for water systems

- Corrosion, chemical and abrasion resistant including against hydrogen sulphide.

- Internal surface protection to avoid the release of particles and debris that clog valves and pipes and contaminate supply.

- Resists bacteria and microbial growth.

- Excellent waterproofing capabilities with the right film thickness and correct application.

- Nil water absorption (with test reports available).

- Compliant with AS/NZS 4020 Potable Water standards

Client Projects

Level best: a precision concrete repair for Sydney Water’s digester

See how Megapoxy 206 Ultra was used for precision concrete repair and levelling – creating the perfect surface for Sydney Water’s massive digester cover.

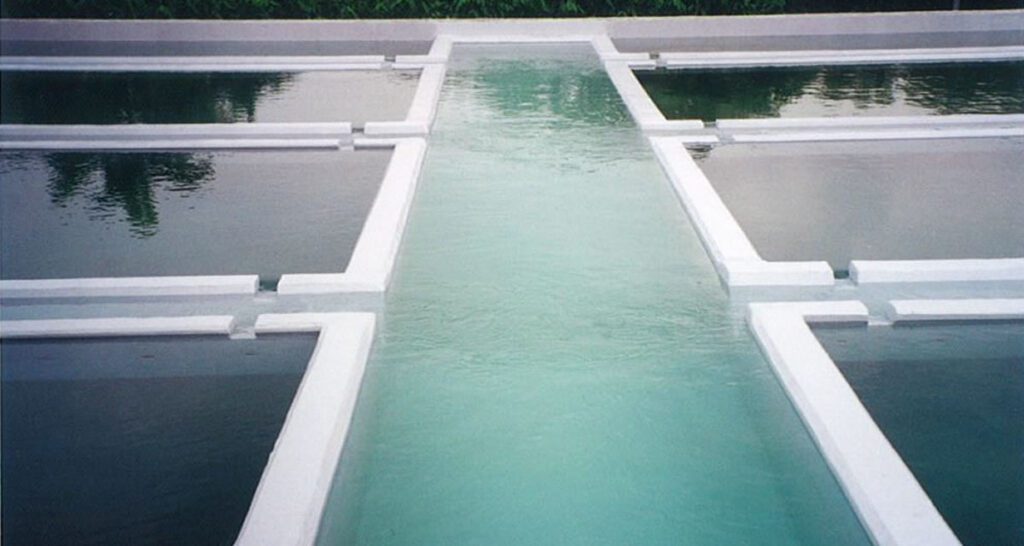

Epoxy for Water Facilities: a 30-year success story from Singapore

This lime saturator was repaired and returned to service in the 1990s. It shows how high-quality epoxy systems can extend the life of critical water infrastructure.

Rock-solid confidence: coating pre-cast concrete with ease and excellence

We worked closely with Bianco Precast to identify the perfect Megapoxy Solution and them guided to success.

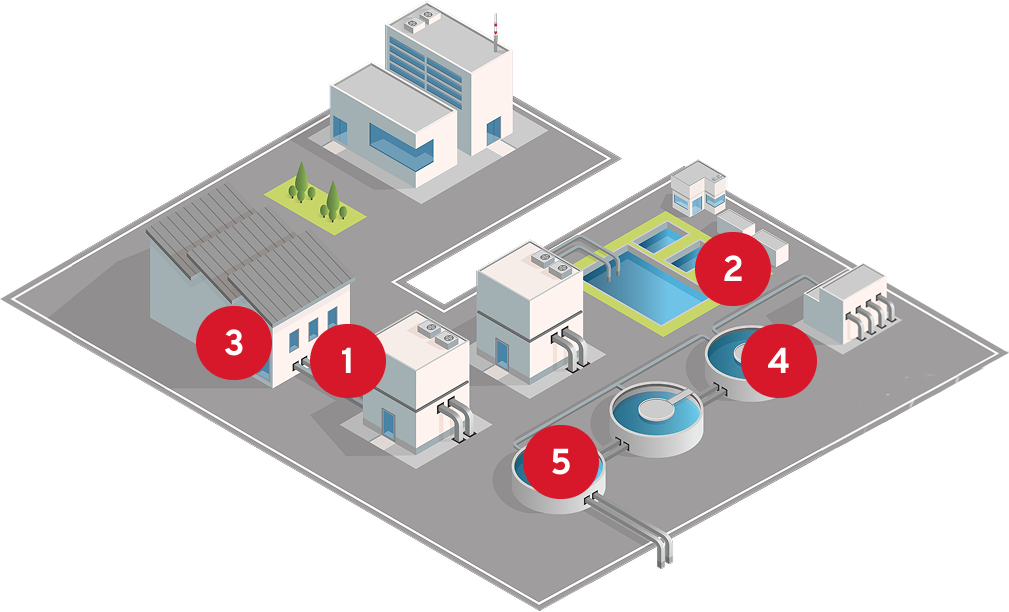

Every stage of water operations

Our formulations play a vital role across entire plants and water facilities.

Trusted across the water & wastewater cycle

Book a technical consult

To choose the right epoxy for your water facilities project.

Browse our epoxy solutions for water facilities

- High-strength structural epoxy paste

- Bonding materials and repairing cracks and defects in water infrastructure.

- Key benefits: Potable-water safe, resistant to hydrogen sulphide, suited to underwater and splashzone repairs.

- Heavy-duty epoxy grout for anchoring and stabilising.

- Anchoring pumps, filling voids and grouting under heavy machinery.

- Key benefits: Potable-water safe, resistant to hydrogen sulphide, suited to underwater and splashzone repairs.

- Heavy-duty maintenance coating.

- Protecting tanks, pipes and clarifiers against chemicals and abrasion.

- Key benefits: Potable-water safe, resistant to hydrogen sulphide, suited to underwater and splashzone repairs.

- High-strength epoxy adhesives for bonding and repair.

- Wet-to-dry bonding, crack repair, patching and anchoring in water infrastructure.

- Key benefits: Potable-water safe, resistant to hydrogen sulphide, suited to underwater and splashzone repairs.

- High-strength epoxy adhesive for surface repairs, protection, and sealing.

- Waterproofing and protection of concrete and timber, food-and-beverage and drinking water safe, factory and sporting-complex environments.

- Key benefits: Potable-water safe, resistant to hydrogen sulphide, suited to underwater and splashzone repairs.

- Heavy-duty abrasion-resistant epoxy coating for high-wear surfaces.

- Strong chemical durability for wastewater environments, creates a hygienic, dust-free protective surface.

- Key benefits: Heavy-duty abrasion resistance, strong chemical durability for wastewater environments, creates a hygienic, dust-free protective surface.

- Abrasion-resistant epoxy paste.

- Lining and repairing pumps, aerators, screw conveyors, tiles and high-flow pipes.

- Key benefits: Potable-water safe, exceptional wear resistance, prolongs service life in harsh environments, available in standard and quick-set formulations.

- Hydrophilic epoxy adhesives for bonding and filling.

- Resistant to hydrogen sulphide, suited to underwater and splashzone repairs.

- Key benefits: Potable-water safe, resistant to hydrogen sulphide, suited to underwater and splashzone repairs.

Certified confidence

- APAS-recognised manufacturing unit: approved under the Australian Paint Approval Scheme.

- ISO9001:2015: international benchmark for quality management systems.

- AS/NZS 4020:2018: potable water certification available on key products (colour-specific).

- Water absorption test report: available upon request.

Benefits of Megapoxy in water facilities

- Excellent resistance to chemicals, corrosion and abrasion.

- Reliable curing in damp and submerged conditions.

- Long-term durability in harsh wastewater environments.

- Easy to specify with clear data, instructions and expertise.

- Reliable supply and support across the world.

- Fast, simple application to reduce downtime.

Water Infrastructure FAQs: Potable water, wastewater durability & technical support

Is Megapoxy safe to use in drinking water infrastructure?

Yes. Selected Megapoxy solutions are formulated for water infrastructure in contact with potable water and comply with AS/NZS 4020:2018 Testing of products for use in contact with drinking water. This makes them suitable for tanks, pipelines, treatment plant structures and other assets carrying drinking water.

Will Megapoxy contaminate water or affect taste and odour?

Megapoxy potable-water-grade products are 100% solids, solvent-free and tested under AS/NZS 4020 to ensure they do not release harmful substances or impart taste or odour to drinking water when correctly applied and cured. This provides confidence for water utility managers, infrastructure owners and maintainers managing sensitive water quality outcomes.

What types of water infrastructure can Megapoxy be used on?

Megapoxy solutions are used across water and wastewater infrastructure including tanks, pipelines, treatment plant structures, digesters, tunnels and associated concrete or steel elements. They are also applied in industrial facilities with demanding wet and chemical environments, such as breweries and process drains.

Can Megapoxy be used in sewage and wastewater assets?

Yes. Products like Megapoxy P1 and Megapoxy H are resistant to hydrogen sulphide and other aggressive conditions commonly present in sewage treatment plants, pipes and digesters. This makes them suited to sealing joints, repairing concrete, and providing durable bonding in wastewater environments.

How durable are Megapoxy solutions in constant water and chemical exposure?

Megapoxy solutions for water infrastructure are designed for long-term immersion and deliver high compressive strength, excellent adhesion and strong chemical resistance under adverse and wet conditions. Case studies in critical wastewater facilities show these systems maintaining performance under heat, process chemicals and biogas exposure over major asset lifecycles.

How does Megapoxy help extend water asset life and reduce maintenance?

By providing high-strength bonding, crack repair and protective surfaces that resist water ingress, chemicals and impact, Megapoxy helps stabilise and protect structures so they require fewer repairs over time. This contributes to extended service life, reduced downtime and lower long-term cost of ownership for water infrastructure owners.

Can Megapoxy be applied on damp, wet or underwater surfaces?

Hydrophilic solutions such as Megapoxy H and gel formulations are designed to bond to damp substrates and can be used for underwater or below-waterline repairs, subject to project-specific technical guidance. This enables structural crack injection, bonding and surface repairs where full drying is not practical, such as tanks, channels and marine or submerged assets.

Is Megapoxy suitable for vertical, overhead or complex geometries?

Megapoxy offers epoxy pastes and gels that are thixotropic and non-sag, making them suitable for vertical and overhead applications as well as complex shapes around pipes, joints and penetrations. These products allow installers to build fillets, seal joints and repair detailing without slump, even in confined or elevated plant areas.

Can Megapoxy be used to repair cracked concrete in tanks and plants?

Yes. Low-viscosity hydrophilic resins like Megapoxy H are used for crack injection and deep penetration into porous or cracked concrete, restoring integrity while remaining safe for potable water contact. They can also be combined with selected aggregates to create high-strength epoxy mortars for rebuilding damaged sections.

How does Megapoxy support heavy structural elements like covers, bases and equipment in water infrastructure?

High-flow, high-strength epoxy grouts such as Megapoxy 206 Ultra are used to level and support large components, for example the rim of a wastewater digester or heavy equipment bases. These grouts provide excellent compressive strength, impact resistance and a precision-flat bearing surface to ensure reliable sealing and load transfer.

What certifications and standards do Megapoxy products meet for water infrastructure?

Potable-water-grade Megapoxy solutions comply with AS/NZS 4020:2018 for contact with drinking water and are formulated with low to very low VOC content for safer use in enclosed plant areas. Many products are also specified in civil and water infrastructure application guides that address typical requirements for bridges, tunnels and water assets.

What technical support is available for water infrastructure projects?

Megapoxy provides technical and design advice, application guides and on-site support to help with product selection, surface preparation, mix design, and installation methods for complex projects. This support helps contractors and asset owners deliver reliability and durability for critical water and wastewater infrastructure.